The 928 engine design is very good in

many respects except one - Oiling. The stock engines suffer from the

dreaded 2/6 failure. This happens when the oil pickup is no longer

submerged, for example long sweeping left hand turns taken at high speed.

The G force causes the oil to be pushed back up the oil passages into the

passenger side cylinder head leaving the oil level below the oil pickup.

The main reason this happens is that the original sump baffle was not

effective. Then there is the issue where the drivers side oil drains are that they

are aimed directly at the spinning counterweights, causing severe windage

inside the crankcase. (oil particles suspended in air) The 928 engine also

does not have a very good oil separator so that air ingested into the intake

from the crankcase usually has a high volume of oil in it. I decided to

address both issues in my engine. I incorporated a very comprehensive

crankcase baffle, windage tray, as well as a crank scraper. I also decided to

improve on the factory oil separator.

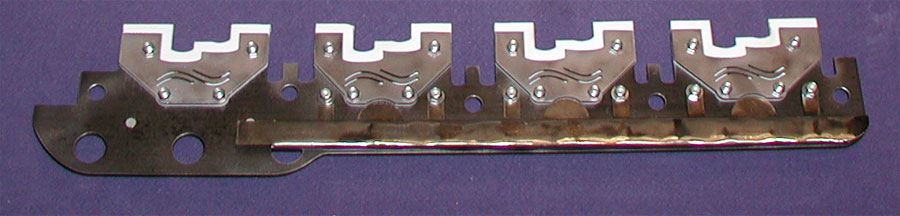

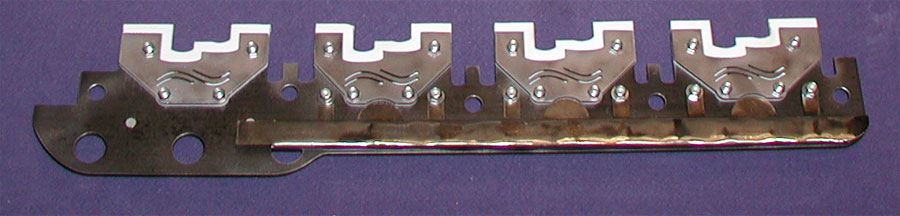

Here is a pic of the Teflon version of

the crank scraper:

I decided to go with the version that

contained Teflon insets. The reason for this was that I needed to trim

the scrapers due to the differences between the stock rods and crankshaft

counterweights. I figured that trimming 4 separate pieces of Teflon

would be easier than trimming one continuous piece of steel. (keep in

mind there are 8 counterweights and 8 rods)

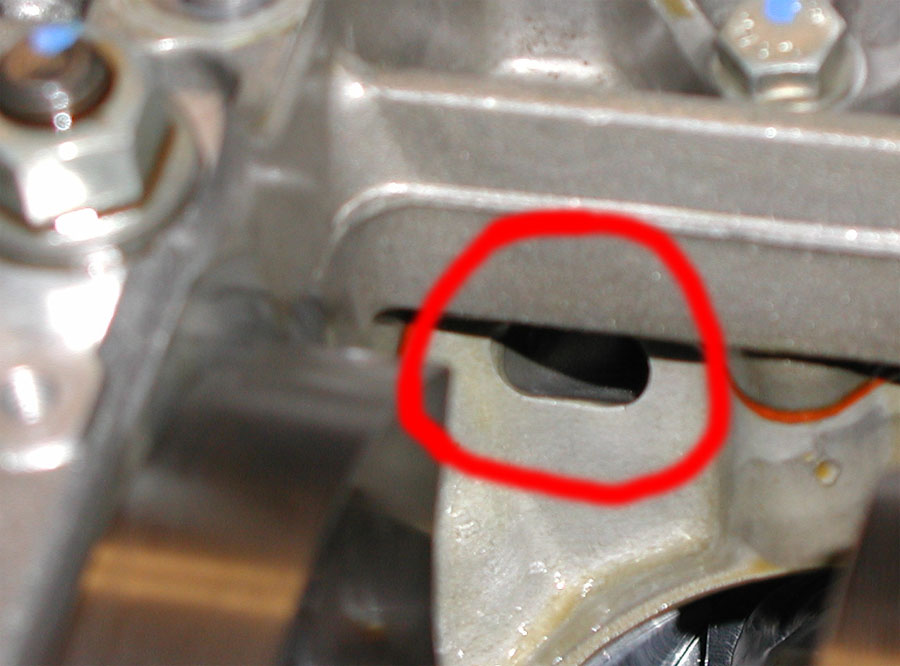

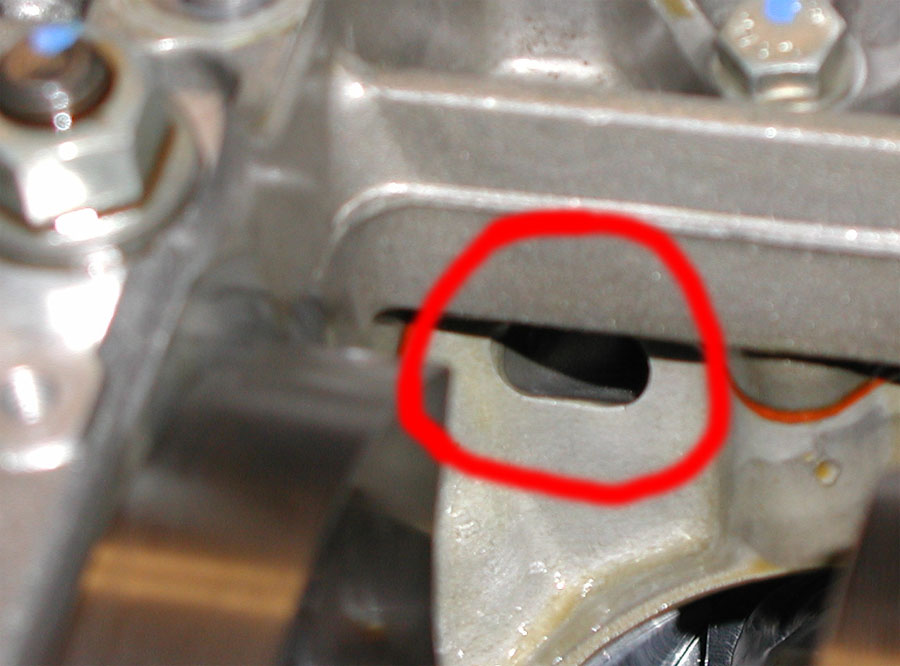

One of the problems with the 928 block

is that there are 4 oil drains from the drivers side cylinder head that drain

right onto the spinning counterweights for the crankshaft creating a huge

windage problem.

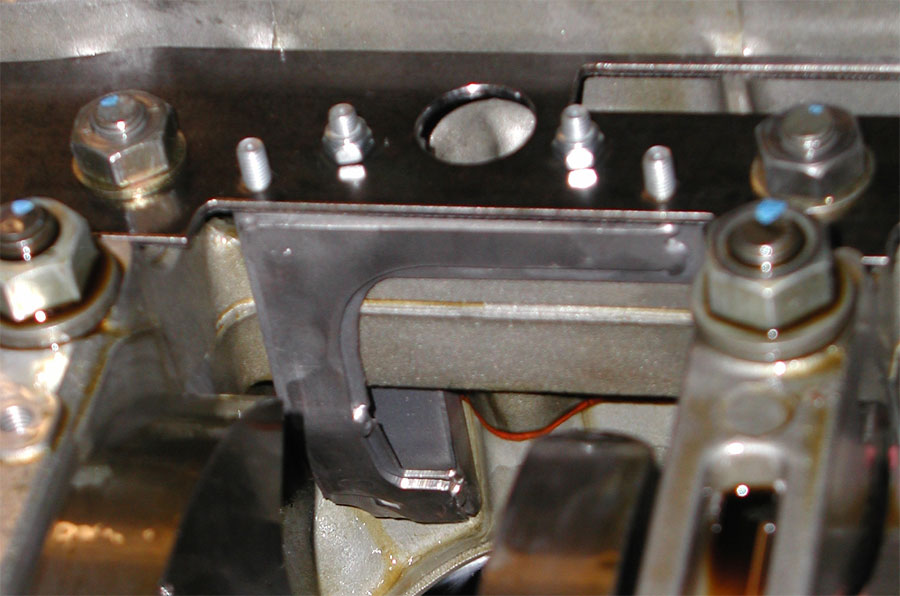

Here is a pic of one of the cylinder

head drains:

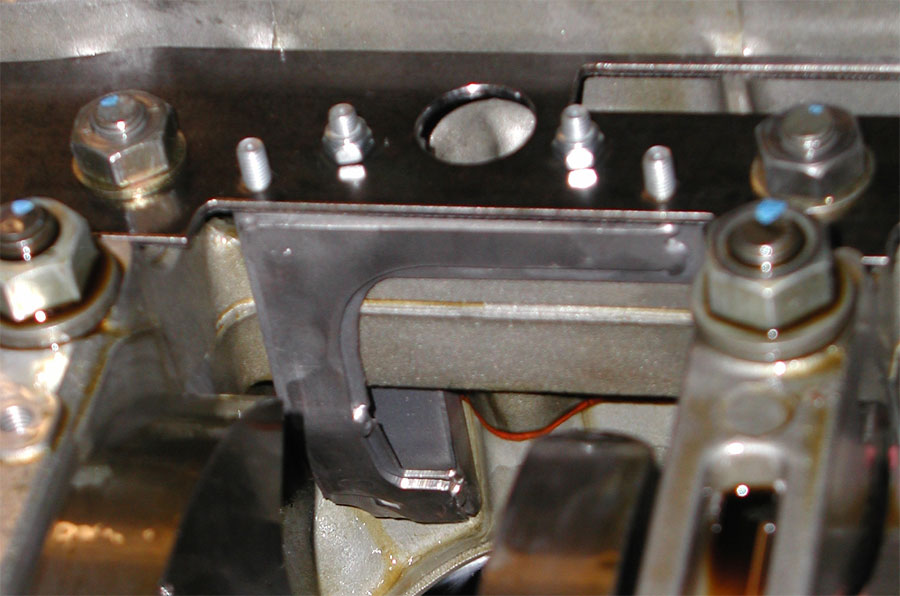

Here is a pic of the oil drain

deflector:

This collection of parts is mounted on the drivers side of

the block. The 4 L shaped pieces are the deflectors that keep the oil

draining from the drivers side cylinder head from draining directly onto the

spinning counterweights. Notice that the oil deflector is multi layered

steel, and is notched for my connecting rods.

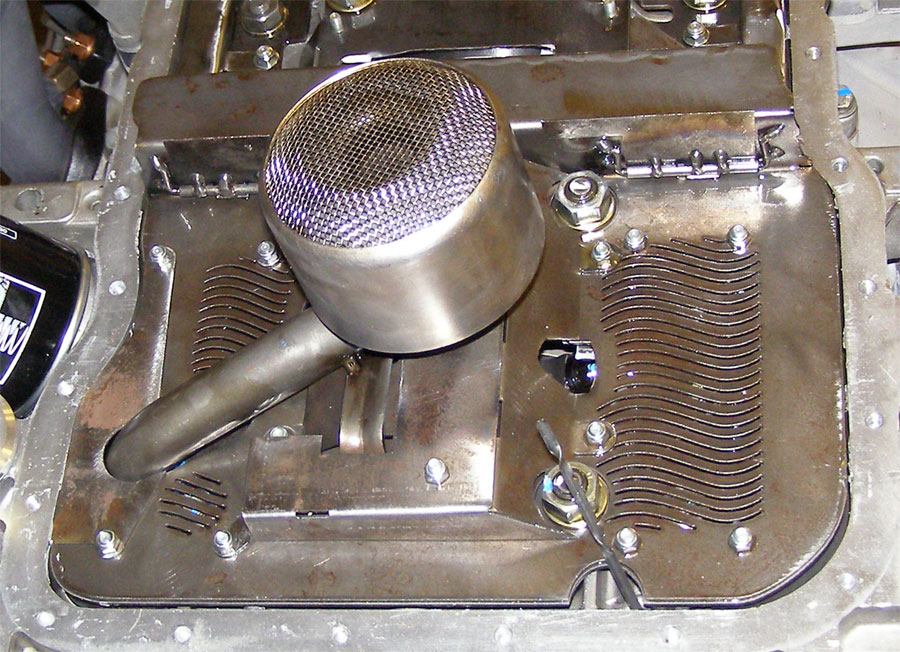

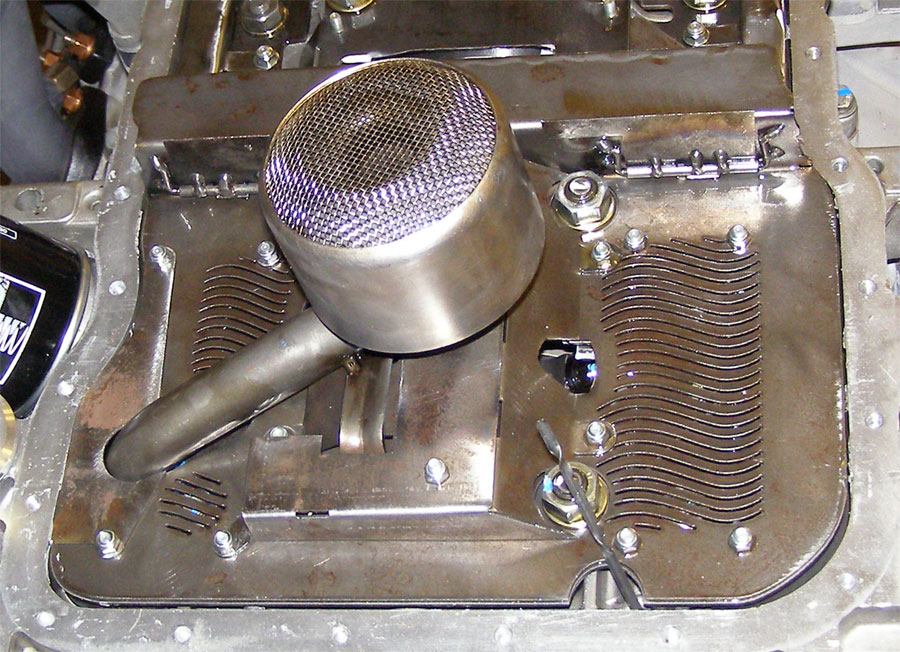

Here is a picture of the oil pan and the

GTS baffle which I installed in the last version:

The problem with the factory baffle is

that it does nothing to keep the oil around the pickup during high G left hand

sweepers. Its also too low. The oil level is actually above the baffle.

Here is a pic of the elevated baffle in

the pan to give you an idea how it looks in the pan, because the pic below

when its installed in the block doesn't really show how it fits the pan, and

well, once the pan is installed you can't get an idea either.

Here is a picture of the elevated

baffle installed.. This is designed to work with the crank scraper and windage

tray

In the above pictures I outlined parts that help

diminish the amount of oil suspended in the air. I also decided to

minimize ingestion of oil suspended in the air into the intake.

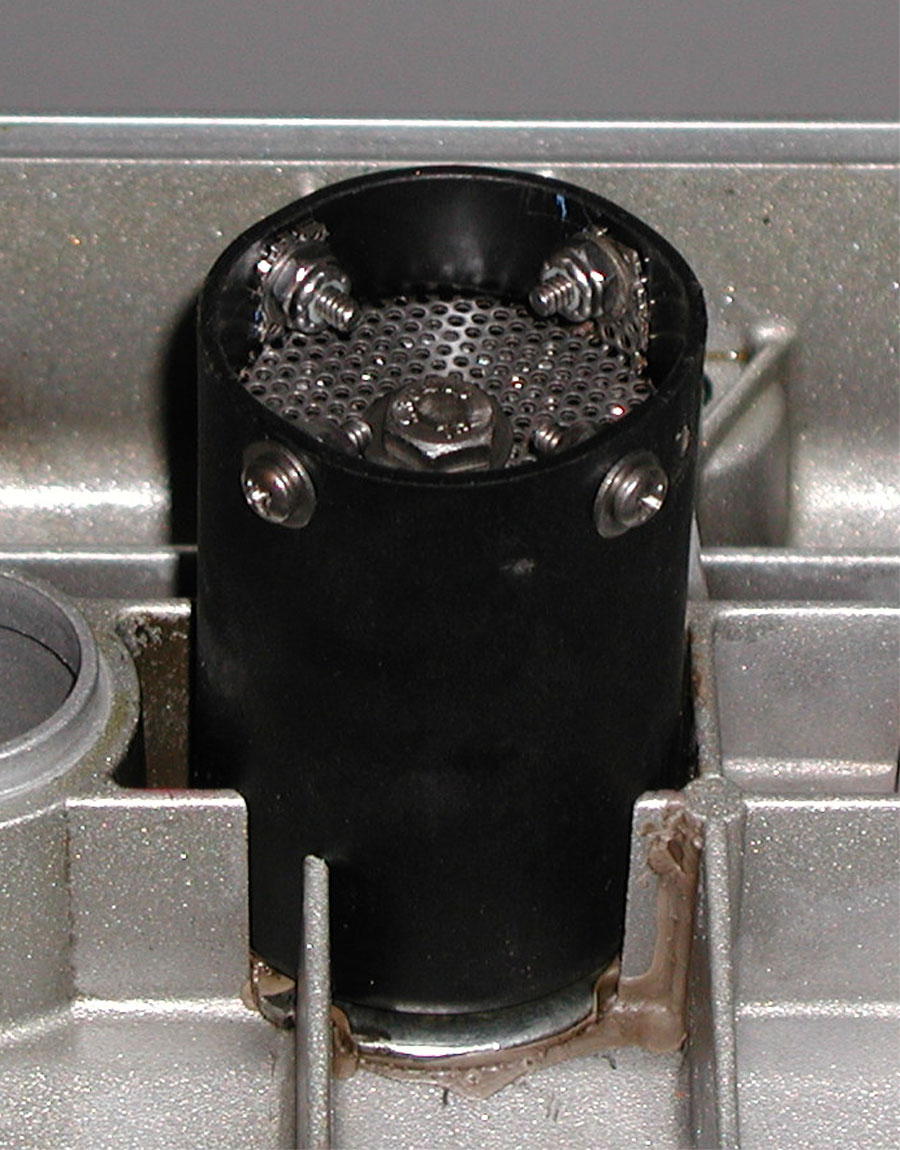

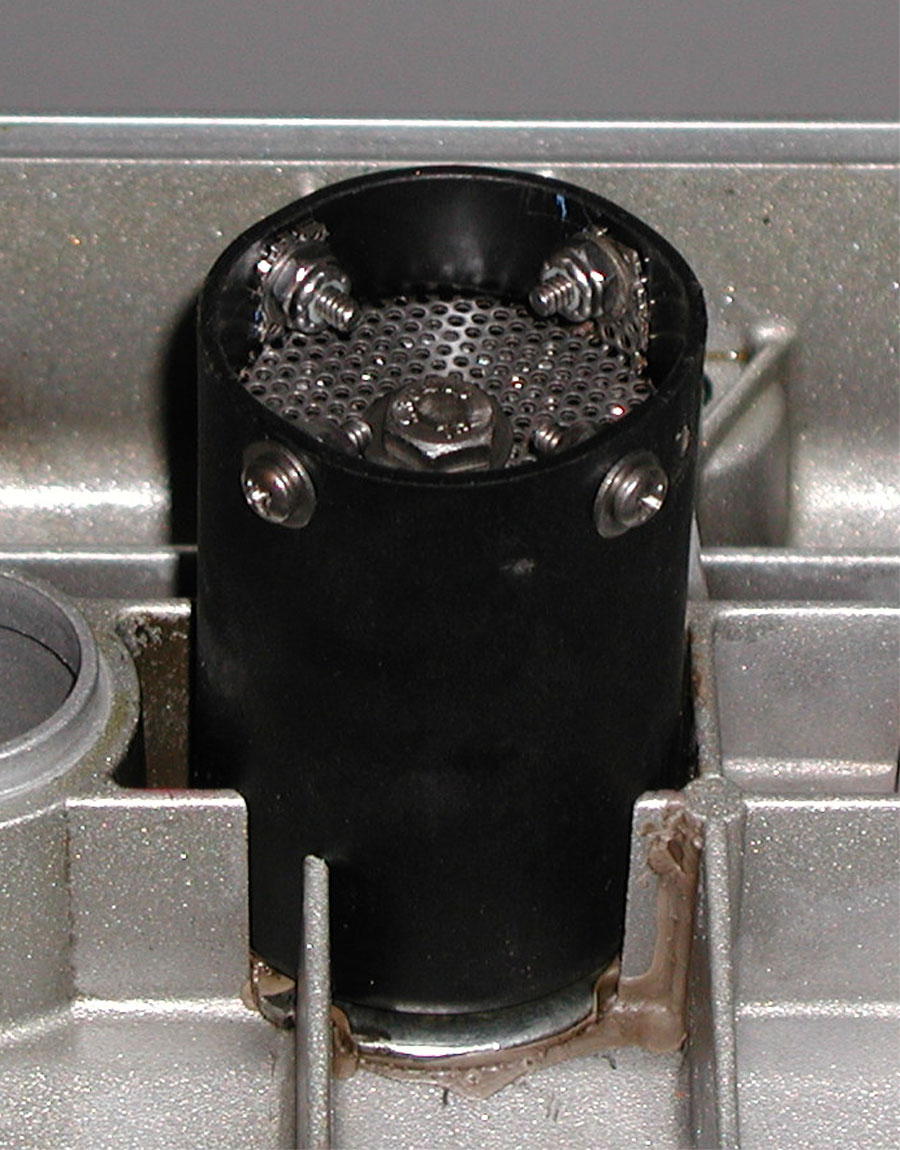

Here is a pic of the factory oil

separator..... if you can call it that... its really simple.

Here is a pic of the separator before

installation.

Here is a pic of it installed:

Heads

& VarioCam

MoTeC

M48 Pro Suspension

Electrical

Cosmetic