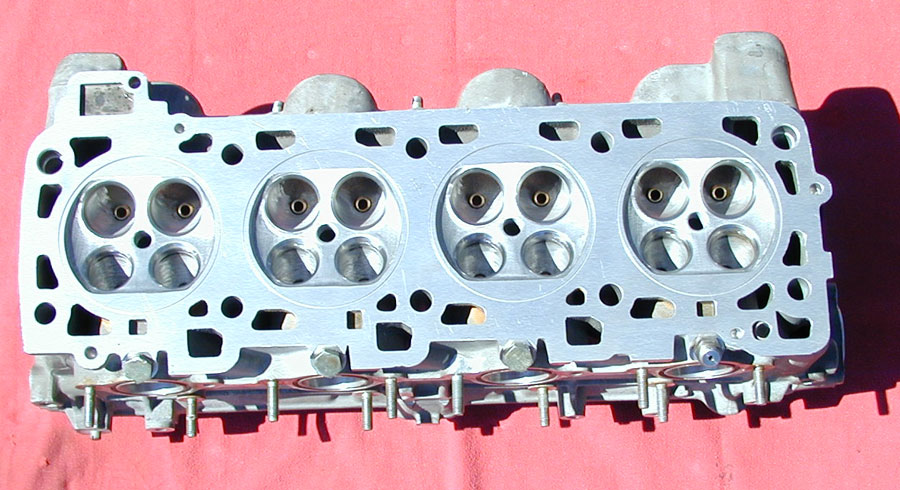

Norwood Performance has had some experience with 928 heads, and the porting needed, along with the larger intake valves from the 968. The heads were disassembled, and sent to Batten Performance for intake porting and fitment of larger intake valve seats. The valve seats were also treated to a 5 angle grind. I bought new stock exhaust valves, and new 968 intake valves, along with new guides and seals, and sent them along to Batten. We also sent the 928 intake so they could port match the intake to the new larger intake ports on the heads. The heads were also machined for o-rings.

After the heads made it back from Batten Performance, we had a major break through on something that I had been wanting to do. I wanted to graft the VarioCam timing feature from the 968 to the 928. Bob Norwood & I had discussed this option early on in the project, but discarded the idea, due to a few issues, that we could not come up with reliable solutions. After thinking about it for months, I went to Bob again, with a new idea, and from this new starting point, we were able to make it work. The 928 heads were modified to accept the 968 cam chain tensioners. The use of the 968 cam chain tensioners require that the 968 Cam covers be used. They actually bolt right on to the 928 head and use the same gasket. The 928 camshafts had to be modified to take advantage of this technology. VarioCam timing allows us to have the advanced opening of the intake valves at a higher RPM, with out the ugly idle characteristics of a hotter cam at idle..

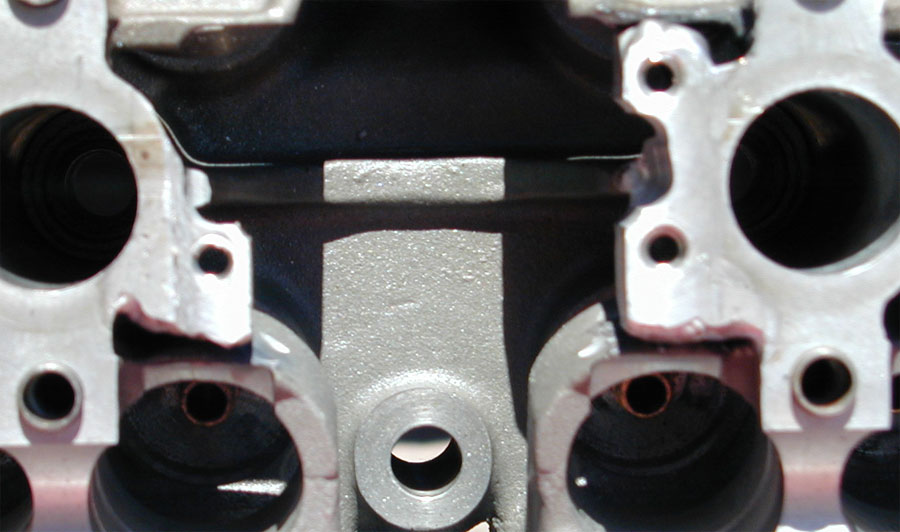

At the heart of the VarioCam feature for the 968, is the chain tensioner. Below are the S4 chain tensioner on the left and the VarioCam tensioner on the right.

Both cam chain tensioners are oil pressure dependent. The higher the engine RPM, and the higher the oil pressure, the more tension exerted on the camshaft chain. Both the 928 and the 968 cam chain tensioner oil supply ports are in the exact same location on their respective heads. The biggest difference between the VarioCam tensioner and the S4 tensioner is the addition of a solenoid on the VarioCam model. This solenoid causes the tensioner to move down, advancing the intake cam 15 degrees. The only difference between the head mounting points are pictured below. The stock head is on the left. The head on the right is my modified head. It's not pretty, but it works great and is similar to the 968 head in design. It just looks like its supposed to be there on the 968!

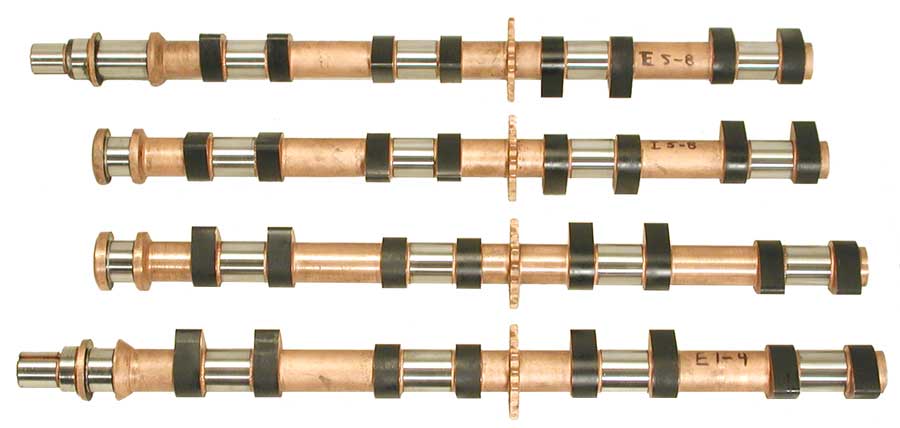

The next difference between the Variocam timing and the stock 928 cam timing, is the sprocket on the camshafts. The 968 and the 928 use the same chain, however, the 968 camshaft sprockets have one less tooth on each cam than on the S4 cams. One less tooth on the intake and exhaust camshafts, allows the VarioCam chain tensioner to move the down off the axis of the rotating camshafts, thus advancing the intake cam timing. The stock S4 camshafts were modified to include a sprocket of the same number and size of teeth as the 968 cams. The stock 928 cam lobes were not aggressive enough, and the "while you are in there" theory, which seemed to be the thesis for this project, over ruled my normally conservative nature and robbed my checkbook for the $$$$.

The RPM at which the VarioCam timing will be activated has not been determined and will be a compromise between maximum HP and drivability.

We also decided to make the new smaller sprockets adjustable on the intake cams. This allows us to dial more advance on the intake side of the house. There are 12 holes machined through the mounting point of the sprocket & the sprocket, including 3 elongated holes that allow approximately 8 degrees adjustment. Each sprocket will be bolted to the camshaft with 3 small high tensile strength bolts. With this configuration, the intake cam timing can be adjusted without removing the cam or the chain. If you look really close to the side of the lobe, you can see the new cam profile compared to the old one....

The above cam and its mates ended up being prototypes of sorts. The adjustable intake sprockets did not hold up as we wished and after our initial dyno tuning one of the adjustable sprockets came loose and broke on engine shut down. So we decided to ditch the adjustable sprockets and just weld on the sprockets like we did on the exhaust. after doing so we sent one of the cams back to the vendor for inspection, as I thought there was a crack in one of the lobes. The cam turned out be be ok, and was shipped back improperly packaged and uninsured and of course it was broken. So the quest for billet cams started. The saga ended 10 months later with billet cams delivered on October 1.

Below you can see one of the intake cams side by side with one of the modified cast cams. If you look really close at the lobes on the cast cam you can see the line on the side of the lobe showing the old profile. It is visible on the rear most lobes

The heads were assembled by James Patterson, as well as the cam timing on the original build in spring of 2002. When the original cams didn't work out, I found out that one of my custom head studs had broken, so I removed one head, and I did the final re assembly of the engine to include the cam timing of the billet cams. I was a bit off on my cam timing, and with the assistance of Bob Norwood I was able to get the cams dialed in properly.