The VarioCam modification increased the cost of the project by approximately 30%, as the factory computer in no way could control the VarioCam timing, and adjust the ignition timing to compensate properly. The only quality alternative for this application in my opinion, is MoTeC. I decided to go with the M48 Pro.

The heart of the M48 Pro is a Motorola 32 bit micro-controller with a time co-processor, a choice which puts it on the leading edge of automotive control systems. Contained in a 132 pin surface mount package and consisting of over 420,000 transistors the M48 is built to internationally recognized quality control standards (ISO 9001). That the M48 reads its sensors 2400 times per second, and the entire control program is recalculated 200 times per second demonstrates its power. In personal computer terms the last PC to use a 16 bit processor was the '286' released in the early 1980's whereas 32 bit is still current technology.

Wiring the M48 Pro in the 928 is not as difficult to do as it initially seemed. After figuring out that the timing belt tensioner warning signal didn't go through the computers, just the through the harness into the fuse panel on the way to the instrument cluster, and finding the tachometer signal output to the fuse panel, it was not bad from there. I hacked up an old burned up harness, for the connector to the timing belt tensioner tap on the timing belt cover and also the connectors where the factory computers connected to the fuse panel. I also saved the connectors to the ignition module, as well. I will be wiring up the in car portion, and then wiring the engine on the engine stand. When the engine is installed, the harness will go through the firewall using the same boot and location as the factory harness, easily plugging into the M48 Pro, installed in the same location as the factory computers. Below you can see my mock engine assembly for the purpose of making the harness.

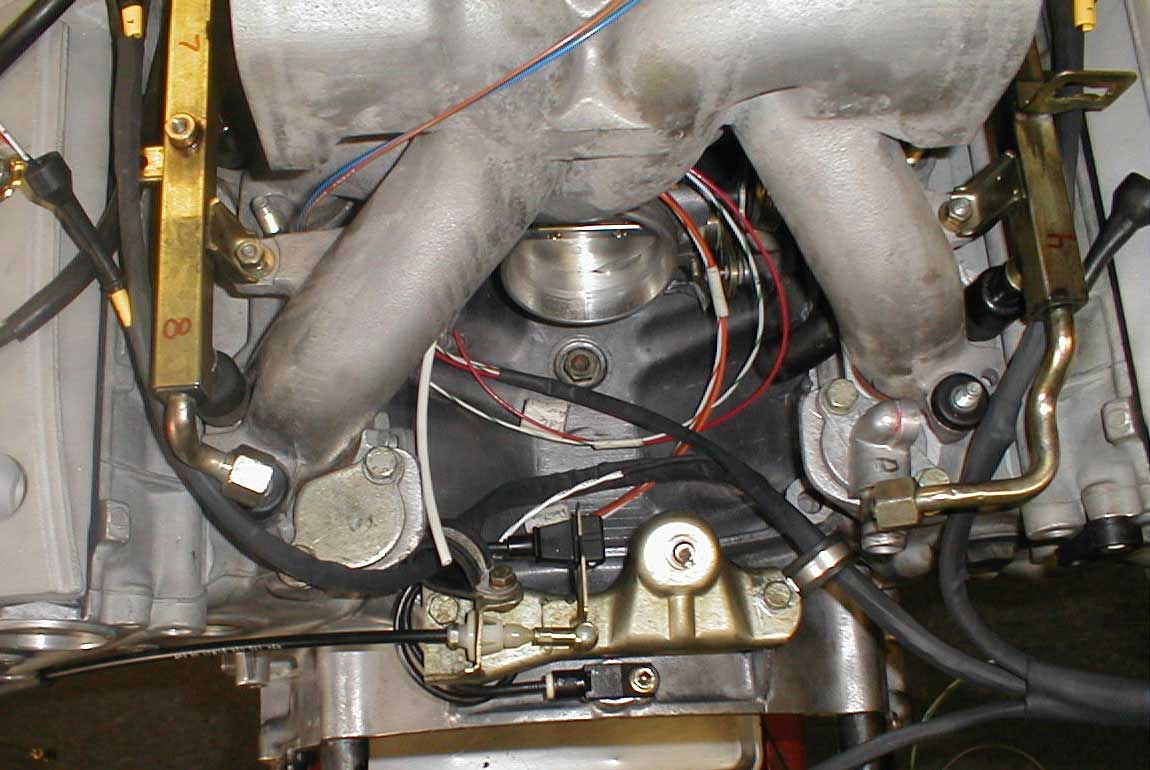

Above, you finally get to see what a 928 engine looks like with 968 cam covers. Due to the shape of the 968 cam covers, I was forced to reroute the spark plug wires as well. In this photo, you can also see the wires for the injectors & VarioCam solonoid sticking out of the harness & connector.boots. Notice the little yellow tabs on the injection harness? Motec includes these with the terminal kit. They have numbers on them for the perspective cylinder, and the sensors will have them as well. They are heat shrinked on the harness. Below is a top view of the area behind the intake. Notice that I made the harness to follow the factory route.

In the above photo, you can see that I have not finished the portion of the harness for the magnetic flywheel sensor (small white coax), nor the Throttle position sensor (white, orange & brown wires). The red and white wire with the green stripe are for the Idle auxiliary control. These will be covered in heat shrink tubing and marked before crimping the terminals and snapping on the connectors. Below is another view of the same area, except it shows the Intake air temp wires in their unfinished state. (blue and brown wires) The harness clamps are larger than what will be used when the harness is completed, but were just used for the mock up to hold the harness in place while making it.

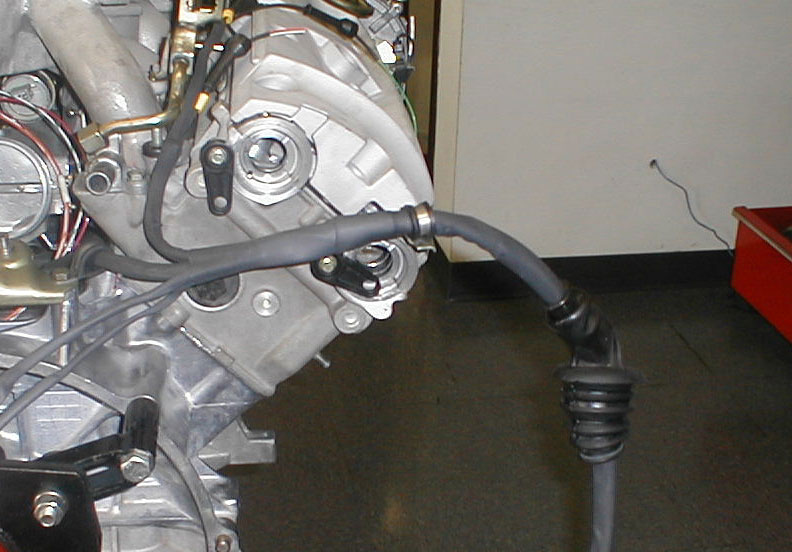

Below you can see what the harness with the factory 928 harness boot looks like. I'd like to thank Mark Anderson of 928 International for that little gem. If it comes on a 928, you can get it from 928 International ! These are not sold by Porsche, and the only way to get one, is to cut a harness in half to get the boot off. Mark had a harness that had been burned in a fire, so it was a perfect candidate.

When it is all said and done, the MoTeC harness is smaller and lighter than the factory harness. The wire used is an aircraft fire retardant insulated, high strand count wire, that was chosen specifically by MoTeC because it handles the high heat of engine compartments without drying or cracking of normal rubber insulated wire used in most cars. Everything about the products that MoTeC sells is first class all the way, from the harness to the crimp kits to the wire marking system. You cannot go wrong with MoTeC!